From design to startup, operational readiness planning is the pinnacle of getting your product to the consumer faster.

What is Operational Readiness? Operational readiness encompasses startup and commissioning aspects, as well as activities that directly support operational excellence and achieve high overall equipment effectiveness (OEE) outputs. Operational readiness may include but is not limited to, process optimization, training and development, capacity analysis and ramp-up planning, takt time, and other activities intended to optimize the operational performance of a system.

In today's food, beverage and consumer products industries, reaching the market first with a unique SKU can generate huge market share. Business decisions are made fast, but it's the engineering teams that need to make these speed-to-market ramp-ups happen. Even with strong intentions and early scoping, targets and deadlines can be hard to hit.

Check out Ken's full operational readiness podcast episode here: Manufacturing Matters.

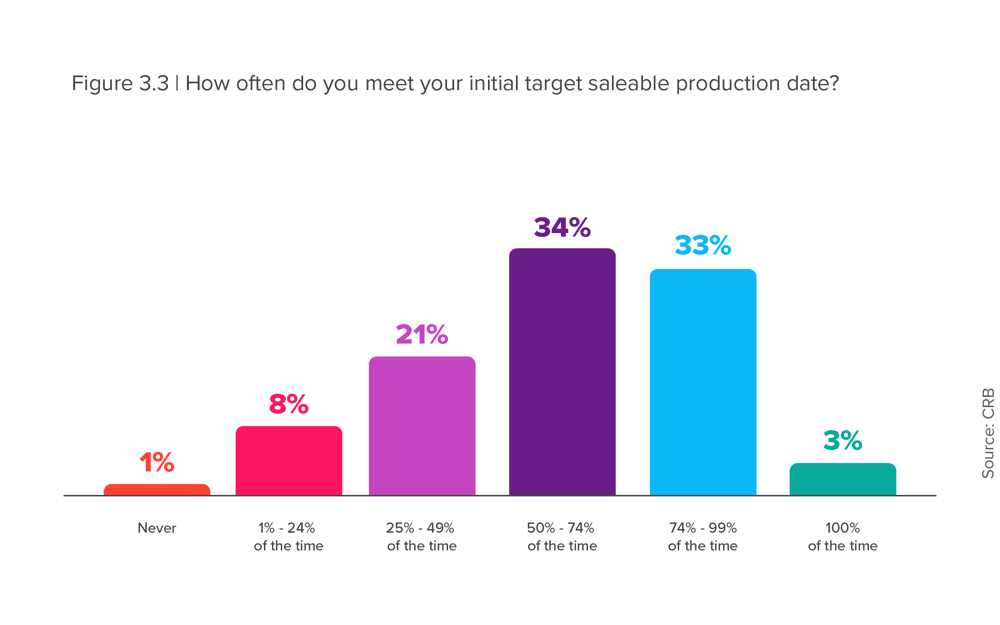

In fact, only 3% of manufacturers reported regularly hitting their target production date, with impacts to speed-to-market coming from every part of the planning process.

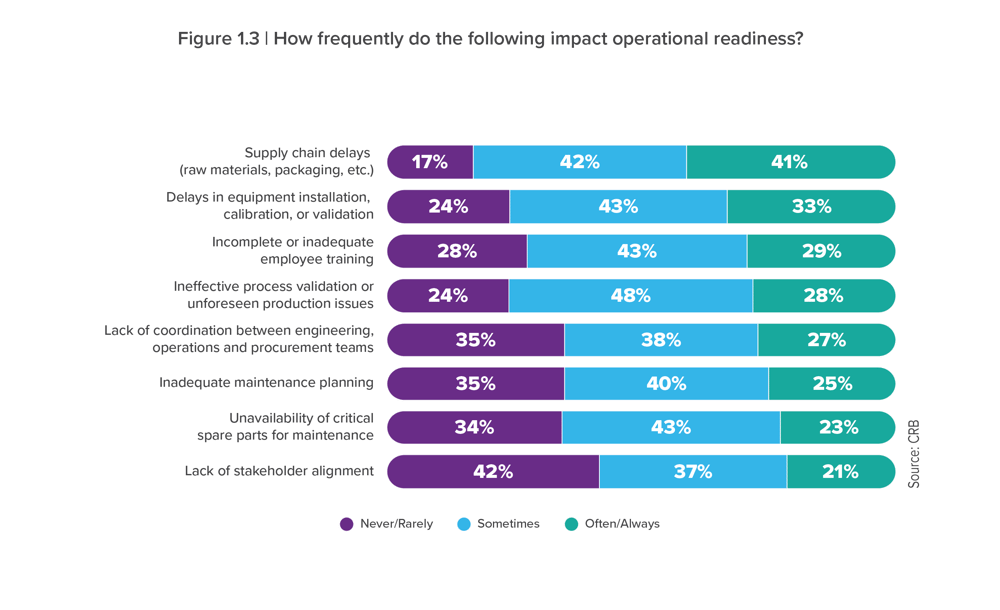

Meanwhile, the plant landscape is changing. More than 60% of respondents are investing in new automation—another challenging aspect for a vertical ramp-up, especially given the lack of skilled labor and training time reported.

Strong, structured operational readiness strategies address four different elements: Minds (your people), Machines (your assets), Materials (your inputs), and Methods (your processes). When all four elements work together, it looks like this:

- The workforce is trained thoroughly and effectively, well in advance of startup.

- The maintenance team has collaborated with OEMs to develop detailed SOPs.

- Materials and ingredients are available at the specified quality, supported by a defined inventory strategy.

- Spare parts are on the shelf because they were budgeted for, and there was a deliberate effort to ensure they were available.

- Equipment is commissioned and verified against real operating requirements, not just installation specs.

- A realistic gap analysis of internal skills and bandwidth has identified where support is needed, and appropriate partners have come on board early in the delivery lifecycle.

While the concept of operational readiness may seem simple, it is underpinned by a complex matrix of interdependent elements (see page 10 of the report for a detailed guide of these operational readiness elements).

What's in the report?

In the 2025 Horizons: Operational Readiness report, our SMEs analyze how CPG manufacturers, big and small, are preparing for and executing new projects to hit their saleable deadlines and target OEEs. Don't let limited time, budget or training stall your schedule and ROI. The Operational Readiness report offers strategies and a free template to help you meet a vertical ramp-up with continued success.

Section 1:

Preparation and planning

- Readiness timing

- Budget allocation

- Internal vs. external

- Critical elements

Section 2:

Toolset development

- Operational procedures

- Tool preparation timing

- Talent and skill gaps

- Downloadable template

Section 3:

Commissioning

- Saleable target dates

- On-time performance

- Success metrics

- Post-startup challenges

Operational readiness is under pressure from all sides. Three-quarters of survey respondents said timeline constraints routinely derail their planning efforts, while 79% pointed to inflation and shrinking budgets as major obstacles.

“If you’ve lived through a missed startup deadline, you know what comes next: scrambling. It’s a period so familiar that it has its own nickname: ‘The Dip’ – that is, the gap in production between your ideal startup and the messy reality that unfolds in the real world,”

--Jason Robertson, CRB’s Vice President of Food & Beverage

This report compiles insights from your peers and competitors. Use it to stay ahead of The Dip on your next CapEx project and achieve your targets.