What We Do

Solutions

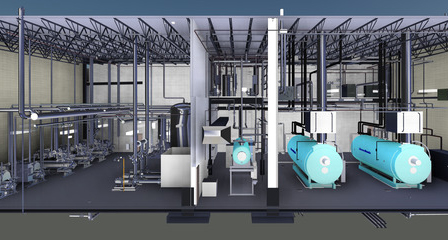

We provide highly specialized technical and construction management services that enable the research, development and manufacturing of food + beverage products.

- Process Engineering and Process Architecture: Meet your business and production needs with our industry-leading process capabilities.

- Mechanical, Electrical and Plumbing (MEP): Maintain a functional, comfortable, efficient and safe environment with highly specialized MEP solutions.

- Architecture: Improve your employees' experience and achieve your business, regulatory and sustainability goals with our award-winning team.

- Safety by Design: Gain a facility that is built safely and designed to operate safely with our Safety by Design approach.

- Clean Facility Design: Address cleanliness and containment through all elements of design and construction with our cross-discipline teams.

- Automation and Adaptive Manufacturing: Build agility into your manufacturing layouts, process design and equipment platforms with actionable roadmaps to facility digitalization.

- Consulting: Unlock value in existing and planned facilities and processes with data-driven consulting services.

- Integrated Project Delivery: Bring your capital investments to fruition, from concept through operational readiness, through our highly collaborative ONEsolution™ delivery method.

Technical Excellence

We pride ourselves on our ability to bring the best technical talent to your project. Our dedicated teams provide subject matter expertise in key manufacturing areas.

Scroll through the image gallery to meet some of our industry-recognized thought leaders.

Renee Benson

Packaging Engineer

Renee is a recognized thought leader in the area of packaging development. She provides extensive experience and knowledge to support design, packaging equipment selection, line layout, troubleshooting and line optimization, packaging material testing and line validation.

Jim Vortherms

Senior Director, Automation Delivery

Jim Vortherms brings nearly 30 years of control systems programming knowledge, including leading teams and the development of control systems. As Senior Director of Automation Delivery, Vortherms helps clients use and manage data to make smarter manufacturing and equipment decisions.

Jerry Steenhoek

Senior Director, Automation Technology

Jerry Steenhoek has nearly 30 years of experience in automation and process systems design, operational technology (OT) networks, and cybersecurity. Steenhoek’s role as Senior Director of Automation Technology enhances CRB’s project delivery by leveraging his automation expertise from early process design through start-up.

CRB Fellowship Program

The Fellowship Program celebrates and enables the technical preeminence of our people. It is a path for our most distinguished professionals to advance their respective area of expertise. As they pursue technical expertise, Senior Fellows and Fellows lead the development and implementation of cutting-edge technologies and innovations and champion growth programs within the company. These individuals are key mentors for fellow CRBers, fostering continuous learning and lighting the career path for others.

- Integrated Project Delivery

- Sustainable Facility

- Alternative Proteins

- Operations Improvement

- Baked Goods

- Refrigerated Petfood

- Beverage/Brewing

Real Results

The Relentless Pursuit of Success. Yours.™

In keeping with our Mission Statement, we measure our success by our clients' success. See how we deliver value across a wide range of project types and technology applications to support safe and efficient food and beverage manufacturing operations.

Integrated Project Delivery

Our ONEsolution methodology enabled Tuffy's Treat Company to increase its production capacity by 500%, maintain its capital budget, and achieve ultra-flexible and safe manufacturing operations.

Tuffy's Treat Company

Tuffy's Treat Company

Sustainable Facility

LEED Gold Manufacturing Facility

LEED Gold Manufacturing Facility

CRB completed all design phases for Mars Chocolate North America's first new facility build in North America in more than 35 years. The facility achieved LEED® Gold certification.

Alternative Proteins

Plant-Based Protein

Plant-Based Protein

Sustainable design reduces water and energy use and costs for large-scale fermentation plant and corporate headquarters for MycoTechnology.

>> See how going vertical reduced MycoTechnology's carbon footprint

Operations Improvement

Operations Study

Operations Study

T. Marzetti gained a 20% increase in kitchen utilization and a 30% increase in weekly throughput with no CapEx investments as a result of a CRB operational study.

Baked Goods

Baked Good Facility

Baked Good Facility

CRB planned, designed and delivered this facility modernization effort that enabled our client to double their production capacity and improve overall food safety and regulatory compliance while maintaining operations throughout the project.

Refrigerated Petfood

Mechanical, electrical and plumbing design for this 140,000-square-foot renovation and expansion of preservative-free pet food manufacturing. Hygienic designs enabled SQF Level 3 certification for the entire facility.

Freshpet Refrigerated Pet Food Facility

Freshpet Refrigerated Pet Food Facility

Beverage/Brewing

CRB's concept through detailed design and construction administration services enabled Boulevard Brewing Company to expand the capacity of its fermentation facility by 40%.

Boulevard Brewing Company

Boulevard Brewing Company